|

Established in November 1994 in Tianjin China and collaborated with Japanese company "Nakamura Bussan KK" in February 1998, our factory Sung Jin has currently 748 employeers in 22,000m2 area |

|

Before

the production is commenced, we study and investigate the product thoroughly

with our various laboratory equipments. |

|

This Place is one

of the busiest division in our factory to fufill the various requirements

of customers rapidly. |

Go to Factory Map |

| Q.C. Division |

|

Even though there

are supervisors for Q.C. in each section of production line, we have

made Q.C. team right under the control of president. They inspect the

finally packed products randomly and the products should be returnde

to the workers unless it is passed this final inspection. |

Go to Factory Map |

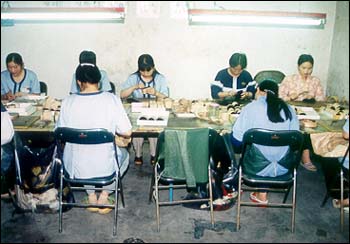

| Production Division |

There

are a lot of works in this division. It consists of 9 sections and each

section consists of 60 workers. Among these 60 workers, 3 workers are

inspectors and they only do inspect products which are being made by their

workers.  |

Go to Factory Map |

| Assembly |

One of

the skillful work is tying the hair to make the double domed blush head

by the workers trained specially. We do make beautiful brushes for Estee

Lauder, Lancome, Chanel and Christian Dior with this tied dome assembly. |

Go to Factory Map |

| Sponge welding |

In order

to make the sponge tip applicator for the eye make up, we use the heat

welding machine. Sponge material is died cut by welding machine with the

glued flexor between. |

|

|

| Injection Division |

| With

12 injection machines, mold temperature controller, automatic crusher

and tumbler mixer, we are injection all kinds of plastic molding products. We have 600 different molds in this room and if is moved speedily by hopper loader for the injection.  |

Go to Factory Map |

| Wood Division |

|

Go to Factory Map |

| Metal Division |

| Raw aluminum

plate is shaped by the power pressing machine and polished. After polishing, it is anodized for color. All the process to make metal products like metal cap, automatic pencil and brush ferrules are made in one place. For anodizing process, we have equipped water purifier and air purifier which are permitted by strict Chinese government.    |

|

|

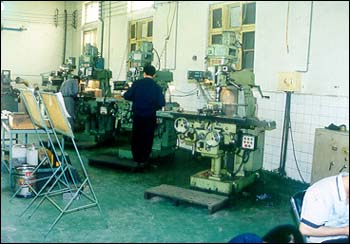

| Tooling Division |

We are

very proud of the high technique of our tool shop. From designing by Auto

cad to completing the mold, all is controlled by our skillful engineers

who are trained in Korea.   |

Go to Factory Map |

| Hot stamping Division |

With

manual and automatic hot stamping machines, we print customer's brand

name on the products. |

Go to Factory Map |

| Silk screening |

Most

of metal products have printing by silk screening and this silk screening

room shoud be very neat in order to avoid any defect due to dust.  |

Go to Factory Map |

| Hair Dressing |

We have

the employeers from northen China who are specialized in hair dressing.

For the high grade brush head, the process of hair dressing is essential.

|

Go to Factory Map |

| Hair Dyeing |

We have

equipped the facility for hair dyeing  |

Go to Factory Map |

| PVC Pouch Division |

|

Go to Factory Map |

| Sterilization |

|

Go to Factory Map |

|

|